4 Steps to Make Your Fixed Ops More Profitable

Fixed Ops profitability is more important for dealerships now more than ever. It can be a source of untapped opportunity for increased revenue that every dealership should be taking advantage of. Thinking about where to begin can seem like a daunting process, so we’ve broken it down to 4 simple steps to get you started.

Step 1: Review your ELR

Step 2: Establish the “Perfect Price”

Step 3: Increase Price Compliance

Step 4: Optimize Technician Capacity

Step 1: Review your ELR

The definition of Effective Labor Rate is simply the average selling price for a flat rate hour. Customer Pay ELR is calculated by taking total Customer Pay Labor Sales and dividing by the total Customer Pay Flagged Hours. It is an extremely important metric and therefore should be closely monitored on a daily basis. So for something that sounds so simple, why is this one of the most complex metrics for a service manager to get their arms around? The reality is most Service Managers really don’t have an idea how much opportunity they have. DMS systems do not provide the information in actionable formats to facilitate ELR improvements or proper variance monitoring.

The biggest reason ELR is complicated is that the metric is typically a rolled up number from all customer repair orders for the day, week, or month, hence the average effective labor rate. In our opinion the total customer pay rolled up average has very little value other than it may highlight an area that needs to be researched further to understand if there is truly actionable variances.

Why is effective labor rate complex to investigate? The biggest reason is that all services are not priced equally. At Dynatron we categorize all op codes into 3 distinct groups: Competitive, Maintenance, and Repair. This was done because services in each of these categories typically require different pricing strategies. When you review CP ELR it should always be at each of these three levels. Any change in the mix of these service categories will cause significant variances in your total CP ELR. Therefore a $5 drop in ELR may not be a pricing/discounting or flagged hour issue but could have been caused by selling a higher mix of competitive or maintenance services versus repairs.

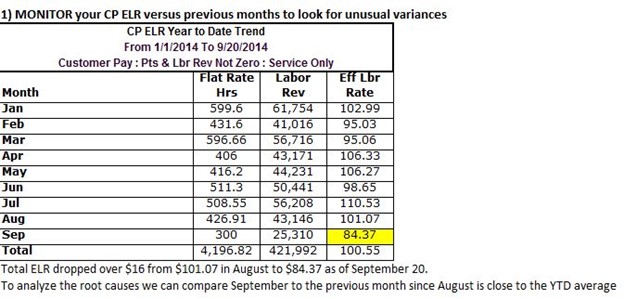

The following example provides a simple process to analyze your CP ELR on a month to date basis:

It is clear that analyzing ELR you should be reviewing the root causes which are sales price and flagged hours versus analyzing ELR fluctuations due to your sales mix of competitive, maintenance and repair items. Certainly, we want to understand why the dealership’s total ELR changes due to sales fluctuations, but the actionable plans for sales mix issues is much different than pricing or flagged hour issues. By breaking this down into its simplest form we can easily determine ELR opportunities and necessary corrective actions.

Therefore, dealerships need to establish a baseline or desired effective labor rate for competitive, maintenance, and repair categories. Variances in each of these categories should be aggressively researched and resolved. If a specific op code’s ELR changed month over month it is either caused by the actual prices charged or the hours flagged.

Step 2: Establish the “Perfect Price”

The definition of the “perfect price” is the price at which profit is maximized, which takes into account the cost behavior of fixed and variable costs and the relationship between price and demand for a product/service.

The price you charge your customers or clients will have a direct effect on the success of your business. Though pricing strategies can be complex, the basic rules of pricing are straightforward:

- All prices must cover costs and profits.

- The most effective way to lower prices is to lower costs.

- Review prices frequently to ensure that they reflect the dynamics of cost, market demand, response to the competition, and profit objectives.

- Prices must be established to ensure sales.

Because pricing decisions require time and market research, the strategy of many managers is to set prices once and “hope for the best.” However, such a policy risks profits that are elusive or not as high as they could be.

When is the right time to review your prices? In the automotive service industry, you should review your pricing strategy when:

- Your costs change. Many costs increase at least 3% per year. As costs increase, your pricing must follow to make the same profits unless you reduced other costs to offset those increases. Technician rate per hour is your highest cost to consider.

- Your competitors change their prices.

- The economy experiences either inflation or recession.

- Your sales strategy changes.

While there are many defined price optimization strategies, the automotive service industry best fits into the competitive pricing model.

The competitive pricing model is generally used when there’s an established market price for a particular product or service. If all your competitors are charging $100 for a transmission service, for example, that’s what you should charge. Competitive pricing is used most often in markets with commodity products, those that are difficult to differentiate from one another. If there’s a major market player, commonly referred to as the market leader, that company will often set the price that other companies within the same market will be compelled to follow.

How to Find the “Perfect Price”

To use competitive pricing effectively, know the prices each competitor has established by completing market surveys. Then, figure out your optimum price and decide based on direct comparison whether you can defend the prices you’ve set. Should you wish to charge more than your competitors, be able to make a case for a higher price, such as providing a superior customer service or warranty policy. Before making a final commitment to your prices, make sure you know the level of price awareness within the market. Once you establish prices, be sure your service advisors are trained on the pricing strategy and, if you are higher than competition, ensure they understand the additional benefits provided to warrant the price difference.

Even though services are essentially the same from shop to shop, service levels can still vary widely. As a result, you can charge a higher fee for a superior service and still be considered competitive within your market.

What are the 3 Sales Categories for the “Perfect Price”?

With the above understanding of effective pricing strategies, you should look at pricing within the three sales categories of Competitive, Maintenance, and Repair.

1. Competitive Service

The competitive service category includes lube, oil, & filter. This category is by far the most price sensitive service to your direct competitors. Because this is the basic service that customers require most frequently, it is essential that you provide a competitive price. Many shops promote additives or premium oils that provide added benefits and justify a higher oil change price.

2. Maintenance Service

Maintenance services include all other time and mileage based services. These services are still somewhat competitive but not as much as you may think. In many carlines, customers are willing to pay a reasonable premium knowing they are receiving service with manufacturer certified technicians and OEM parts. Higher end carline customers are not as price sensitive. Most flush services provide additional warranties through the vendor if performed within specified mileages and thus can be priced at a premium.

One way to increase your ELR on competitive and maintenance services is to package them into a good, better, best menu format. Packaging products to differentiate themselves from competitors was perfected by Sam’s Wholesale Club. They required their vendors to provide the “similar” products in different package sizes which made it much harder for customers to price shop their offerings. Packaging your competitive and maintenance services into menus does the exact same thing. When properly presented, human nature is to select the “middle” option. The customer always has the competitive option so there is minimal risk to sales. Advisors can be trained to highlight the benefits of the better and best options giving the customer the choice.

3. Repair Service

The repair sales category is where you may have the most opportunity to maximize profits. It is still worthwhile to understand the basic repair labor rates of your competitors. Again, understand that everything is competitive to some degree so moderation is the key. OEM parts and OEM certified technicians are a big selling difference for repairs. Customers can easily understand that you are the experts or specialists and thus can relate to reasonably higher prices. Because some simpler repairs may be competitive, a grid pricing structure is often a valuable way to remain competitive but maximize profits.

In summary:

- Complete market surveys for pricing of key competitive and maintenance services and repair labor rate per hour as necessary based on changes in cost, competition, economy, and sales strategy. This is your pricing starting point or baseline. In only very rare cases would you ever price below your competitive rates.

- Analyze each competitive and maintenance service to see where your service levels justify a higher price. Keep the basic LOF competitively priced, but offer premium service options.

- Consider packaging maintenance services into a good, better, and best menu to enable advisors to sell additional services and the value they add. Most dealerships can increase their maintenance ELR $2-$5.

- Consider migrating to a pricing grid for repair services. Most dealerships can easily increase their repair ELR $3-$8 with a properly created grid without losing any traffic.

Step 3: Increase Price Compliance with Service Advisor Training

In steps 1 and 2, we defined ELR, discussed how to analyze this complex metric and reviewed how to optimize selling prices. Once your prices are established, it is critical to monitor that these are the prices actually charged to your customers.

Because you are selling a service, you have only your Technician’s available time to sell. If you have 500 hours available, you can only sell 500 hours. Therefore, the amount of discounts you give to customers can make a huge difference in your profitability.

Why do Fixed Ops Departments Discount?

Before getting into how to monitor your established pricing, lets first review why we discount. We must begin by determining the true root causes of discounts. If the cause is bad estimates possibly due to firm quotes provided to customers on repair work you may want to review your quotation policy. If the root cause is the temptation to discount to sell the service, consider these pitfalls:

- Negotiations over discounts focuses attention only on price as if that were all that matters. If your only competitive advantage is price, you are in trouble, because price can always be matched. Dealerships have a competitive advantage using OEM parts and certified Technicians.

- Discounting can affect the customer’s perception of your service. The less they pay, the less they will value the quality of the service.

- Discounting will affect your profit margins. Consider what would happen if all your competitors met your discounted price. Do you think your customer is going to accept any less quality?

- Discounting may affect the quality of your service. Yet, if you compromise the quality of what you sell, you risk disappointing customers. You may lose repeat business, lose credibility or gain a bad reputation, or end up spending time fixing complaints. One way or another, today’s discounts could rob you of future business and profits.

- Habitual discounting can become psychologically disempowering. A reduced price can be a short-sighted ‘quick fix’ that reduces business growth in the long run. Before you discount, stop and think: Is this the only way to give value?

Be mindful when you’re offering a discount. Ask yourself these questions: Why are you doing it? Is it an investment, and will it get you future benefits? Is it something you do all the time, a habit? Are my Advisors trained on overcoming price objections? Are you offering a discount as the ‘lazy way out’ instead of making the effort to explain or demonstrate your value?

Here are the some critical steps to monitor and control discounting:

- Be sure op codes are properly setup in your DMS to enable proper price monitoring

- Create a policy on when and how Advisors will respond on significant price variances

- Ensure Advisors are trained to be aware of: all pricing, why discounting is not always a good business choice, how pricing will be monitored

Create a Pricing Compliance Policy

Once you understand the above concepts and current discounting reasons, create a policy or discounting guideline and properly train your advisors on the policy and overcoming price objections. This helps Fixed Ops leaders and technicians alike to be aware that there is a lot of money on the table if you can monitor and control it.

Part 4: Optimize Technician Capacity

In part 1 we reviewed that ELR consists of two critical metrics: Labor Revenue and Flagged Hours. In parts 2 and 3 we discussed optimizing prices and controlling discounts to your established price. The Flagged Hours half of the ELR equation is the piece most commonly overlooked. We agree that the “biggest bang for the buck” is in optimizing and controlling labor pricing. However, controlling flagged hours plugs a potential profit leak.

Defining the Automotive Flat Rate Compensation System

Automotive Technicians are generally paid by the amount of work they produce (known as “flat rate” compensation). Under the flat-rate pay system, the Technician is paid by the job. If a job that is estimated at one hour takes three hours to complete, the employee is still paid at the flat rate, the equivalent of one hour. However, if he completes the work in just 30 minutes, he still receives the full flat rate. Technicians working for a flat rate have the potential to triple their earnings. By design, the flat rate system encourages Technicians to work fast and efficiently.

By this definition alone, we can assume some potential issues that need to be controlled. Ask yourself these questions:

- How do you monitor comebacks? If Technicians are motivated to complete their work quickly, does this produce poor quality? If so, you will have comebacks, reduced CSI, and poor retention.

- Are your flagged hours set up correctly in your DMS, by op code where possible, and at industry standards?

- Do you monitor flagged hour fluctuations by service?

- Have you trained Advisors and Technicians on properly completing job estimates and properly presenting these to customers?

- Do you have written policies spelling out when preset flagged hours can be changed and what the approval process is?

To illustrate the potential ELR profit leaks, let’s review a real example:

Assume your service department has a $100 door rate. A customer visits and requires a water pump, which, according to your flat rate hour guide, pays the technician 2.5 hours. Labor sales come to $250 ($100 x 2.5). If the pump costs $125, parts and labor for the job is $375 before tax and shop supplies. Add $25 for tax and shop supplies and the total price quoted to your customer is $400. Effective labor rate (ELR) is labor sales dollars divided by flat rate hours paid to the technician for getting the job done. In this example, it’s $250 / 2.5 hours = $100 which is the same as your established door rate.

Now let’s say the Advisor and/or Technician messed up on the estimate and didn’t allow for a gasket that costs $20. The advisor assumes the customer will be mad if the job exceeds the estimate, so he goes in and subtracts $20 off the labor sales dollars paid. This brings labor sales dollars down to $230. Your tech is not about to accept anything less than the 2.5 flat rate hour allowance so ELR is now down to $92 ($230 / 2.5 hours).

It could get worse! Let’s assume there is a broken bolt, and the Technician tells your Advisor that he has to be paid for at least 2.7 hours because the bolt is stuck. Your service writer says he didn’t flag the job for 2.7 hours, but your tech says it doesn’t matter, that’s how long it will take him. He wins and ELR is now down to $85.19 ($230 / 2.7 hours).

This is just one customer and one job, but similar situations happen on an estimated 25% of the jobs in the service department.

This can be partially eliminated by training Advisors to provide a better word track to the customers for more complex estimates that allow for possible adjustments due to complications or additional parts once the service is better understood. If the Advisor and/or Technician explain the issue to the customer properly with possible photos, the customer should be ok with the adjusted price because proper expectations were made during the quotation process. In minor cases, the dealership may elect to adjust labor thereby lowering their ELR versus adjusting the customer’s price or Technician’s pay. These should be approved by the manager.

Increase your Fixed Ops Profitability with Dynatron Software

Dynatron is dedicated to making your Fixed Ops easier and more profitable. By using our proprietary advanced ROI analytics platform, in particular our Virtual Performance Group (VPG) and our Mystery Shop Intelligence, our expert coaches will work with you to identify the perfect repair and maintenance price for retention and profitability. Another way CP ELR is continually optimized is through automated compliance reporting. This provides your management team a quick daily accountability process for coaching service advisors. It is imperative to maximize your CP ELR prior to filing your warranty labor rate, as it significantly improves your opportunity. Get started with a product demo today!